PRODUCTION MONITORING SOFTWARE

Quantum Real-time Production Monitoring System provides unparalleled visibility into manufacturing operations, helping businesses track performance, detect inefficiencies, and make data-driven decisions.

Quantum InformationBoost Productivity with

Production monitoring

Quantum is the ultimate productivity-boosting system, designed to reduce waste, maximize uptime, and enhance manufacturing efficiency. Easily installed on any machine in just a few hours, Quantum seamlessly connects your ERP/MIS system with your production equipment. It automatically retrieves job data from your MIS, guiding machine operators to meet production targets while fostering a culture of continuous improvement.

Machine monitoring hardware

Efficiency Management Units (EMUs) are an integral part of the Quantum Production Monitoring System. Easily installed on your production machines in just two hours, EMUs provide real-time machine monitoring. They log every second of machine activity and track all waste material. They also keep machine operators fully informed of production targets and real-time job progress, ensuring optimal efficiency and performance.

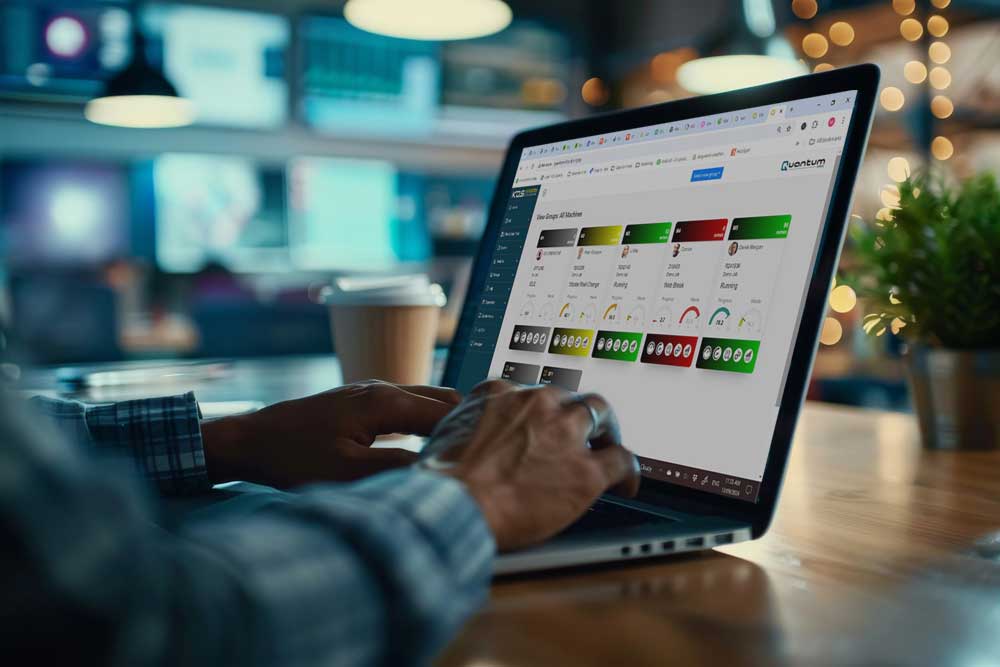

Production status insights

Stay informed in real time with instant insights into what’s happening on your production floor, when it’s happening, and why. Quantum’s unique Virtual Shop Floor provides seamless access to live productivity data directly from your machines, ensuring complete operational transparency. Instantly see which jobs are running smoothly, where potential issues are arising, and whether any tasks are at risk of delay. With Quantum, you gain the ability to proactively address production challenges, optimize efficiency, and ensure on-time job completion—keeping your operations running at peak performance.

Real time production dashboards

Quantum keeps your production staff fully informed of real-time and post production KPIs. Numerous dashboards provide KPI at different levels such as current job, completed jobs and overall production department. At any minute of the day you will instantly know if you are falling behind.

Production reporting

Quantum has over 130 printable production reports as standard, totally eliminating the need for machine operators to produce manual job and machine logs. Every job is constantly monitored providing invaluable insights into productivity and waste. Quantum Reports show where you are losing time and where you are losing money.

Machine tachographs

Quantum continuously tracks machine speeds and activity every second of the day, storing up to seven days of real-time production monitoring data. With the Quantum Tachograph utility, managers can visually analyze past production runs, pinpoint inefficiencies, and investigate the root causes of downtime or performance issues. This powerful tool provides actionable insights to optimize machine utilization, improve productivity, and drive continuous operational improvements.

Production KPIs

KPIs (Key Performance Indicators) are measurable values that indicate how effectively an individual, team, or organization is achieving key business objectives. They help track progress, identify areas for improvement, and guide decision-making.

Quantum Production Monitoring Software delivers real-time operational KPIs instantly, giving management instant access to critical performance insights at the click of a button – anytime, anywhere.

Overall Equipment Effectiveness

Overall Equipment Effectiveness, or OEE for short, is a widely used system of production metrics used for standardizing and measuring manufacturing productivity. It is one of the fundamental concepts in Lean Manufacturing.

Quantum is continuously monitoring all key metrics of OEE and provides both machine operators and front-line managers with OEE in real-time. Any machine equipped with an Efficiency Management Units can benefit from these invaluable insights.

Andon boards

An Andon board is a large display that features significantly in modern factories. Its purpose is to notify management, machine operators and other employees of current manufacturing KPI’s, and to keep everybody fully informed of progress against targets. KDS can build custom Andon boards to your own specification, presenting the data that you need in a way that suits you best.

Free Quantum Whitepaper

Get this free whitepaper and learn how Quanum Efficiency Management System can help you reduce manufacturing waste and achieve higher productivity with your existing machines.

Reach your full potential

Watch our Quantum video to discover the game-changing benefits you’re missing out on. Don’t get left behind—embrace the Industry 4.0 revolution and unlock the full potential of smarter, more efficient production. See how real-time monitoring, data-driven insights, and optimized workflows can drive productivity, reduce waste, and maximize profitability.

Reduce Waste

Quantum helps identify and eliminate waste in processes, i.e. materials, time and labour and helps improve overall efficiency.

Reduce Downtime

Quantum identifies reasons for downtime, enabling managers to investigate root causes and plan corrective proceedures

Improve Visibility

Real-time production status updates keeps everyon informed. Small issues can be identified quickly and addressed, before they turn into big prodlems

Employee Empowerment

Quantum helps identify and eliminate waste in processes, i.e. materials, time and labour and helps improve overall efficiency.

Improve Efficiency

Quantum helps identify and eliminate waste in processes, i.e. materials, time and labour and helps improve overall efficiency.

Increase Productivity

Quantum helps identify and eliminate waste in processes, i.e. materials, time and labour and helps improve overall efficiency.